The Watkinson Patent Plane

One of the curious oddities in Australian plane making over the last 80 years has been the designs and patents of Herbert Edward Watkinson in the 1930’s. At the time H.E. Watkinson was a cabinetmaker residing in Launceston, Tasmania who had developed a plane in which the pitch, or cutting angle, of the blade could be adjusted from a normal bench plane angle of about 45 degrees, to a scraper plane with the blade set at almost 90 degrees to the work. Why this would be so useful to the average woodworker in a cabinetmaking workshop or factory is anyone’s guess, as it would have probably been easier to just use a couple or so “fixed bed” planes of varying pitches, rather than a jack-of-all-trades specialized plane to do the work required.

One of the curious oddities in Australian plane making over the last 80 years has been the designs and patents of Herbert Edward Watkinson in the 1930’s. At the time H.E. Watkinson was a cabinetmaker residing in Launceston, Tasmania who had developed a plane in which the pitch, or cutting angle, of the blade could be adjusted from a normal bench plane angle of about 45 degrees, to a scraper plane with the blade set at almost 90 degrees to the work. Why this would be so useful to the average woodworker in a cabinetmaking workshop or factory is anyone’s guess, as it would have probably been easier to just use a couple or so “fixed bed” planes of varying pitches, rather than a jack-of-all-trades specialized plane to do the work required.

It is possible, however, that Watkinson felt that a variable pitch plane would be of a great advantage to the journeyman woodworker or an “on site” carpenter, who would only need to pack the one plane in his toolbox to take to a job, rather than several. This would be a valid proposition as the most successful maker of metal woodworking planes, Stanley, often applied this way of thinking to many of the planes in its range, most notably the No. 45 and No. 55 combination planes.

Design

It should be said that there are only four examples of the Watkinson Patent plane that are currently known – three black, earlier patent types, and one green plane which is a later type. Style-wise, the plane is similar in body shape to a Bailey plane or a Stanley Gage plane, with a pointed side profile sweeping all the way back to the heel. The lever cap is a Stanley cam type and both the tote and knob are made from a light colored wood with a honey-colored finish. The depth of cut for the blade is also similar to a Stanley Bailey adjustment, with a knurled brass knob rotating on a threaded steel pin and moving a yoke to position the blade.

The three early model planes feature two “screw access” holes which are machined through the base of the plane, allowing for the adjustment of the bed angle from underneath the plane. Not an ideal situation, but it works.

The later plane is without these two access holes, which suggests that it was probably considered a “production” model – though how many of these planes were actually produced is anyone’s guess? The fact that all of the planes found so far were bought from sellers in Tasmania indicates that the planes did not get beyond the initial prototype phase, or that there was a (very) limited production run.

The later plane is without these two access holes, which suggests that it was probably considered a “production” model – though how many of these planes were actually produced is anyone’s guess? The fact that all of the planes found so far were bought from sellers in Tasmania indicates that the planes did not get beyond the initial prototype phase, or that there was a (very) limited production run.

At least two of the planes have “PAT. APP. 3114/31” (1931) crudely pop-stencilled in the sides with a center punch. The green, later model plane, also has the maker’s name cast into the bed on either side of the rear handle. The raised type is in two lines and reads:

PATS APPLIED FOR

H.E.WATKINSON

It should also be mentioned that both the body casting and the frog are rather crudely done, with plenty of air bubble holes, casting flaws and machining marks. None of these flaws detract from the usability of the plane but it would suggest, once again that these planes were pre-production models, rather than finished models.

Specifications

The Watkinson Patent plane is a heavy smoothing plane around about the same size of a Stanley No 4-1/2. The green plane, which was bought on eBay in 2004, came with a 2-3/8″ double iron which was marked “Stanley Australia”. It’s assumed that this blade is a later addition as Stanley Australia started production in Tasmania much later than 1931.

The plane was in pretty good condition and it would be reasonably safe to assume that it hadn’t seen a lot of work in its lifetime. It does appear, however, that the top of the rear handle has broken off at some stage and has been repaired (in the form of a “roundover”). It would be expected that the original shape of the handle would be the same as that found on the earlier black planes.

Â

The overall length of the plane is 10-3/4 and the width is 2-3/4″. The patented feature refers to the adjustable frog which, as mentioned previously, allows the plane to operate at different cutting angles. For some reason, only known to the maker himself, the frog is not hinged to the sole as would be expected of such a design. Instead there are two internal screws that extend from the back to the front of the frog, and allow the two-part frog to move upwards and forwards (or backwards) – thus adjusting the width of the opening of the mouth for the different settings. There are two screws through the slides at the rear of the frog which actually fix it into position.

The overall length of the plane is 10-3/4 and the width is 2-3/4″. The patented feature refers to the adjustable frog which, as mentioned previously, allows the plane to operate at different cutting angles. For some reason, only known to the maker himself, the frog is not hinged to the sole as would be expected of such a design. Instead there are two internal screws that extend from the back to the front of the frog, and allow the two-part frog to move upwards and forwards (or backwards) – thus adjusting the width of the opening of the mouth for the different settings. There are two screws through the slides at the rear of the frog which actually fix it into position.

The wood on a couple of the planes looks re-finished, as does the finish on the castings. The former owner of the green plane, however, has stated that this is exactly the color used in the originals — black for the earlier model and green for the later type.

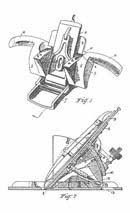

The designs for the planes were patented in 1931 and 1933 respectively. The 1931 patents are for two tools – a variable pitch bench plane around the size of a Stanley No. 4, and an adjustable spokeshave-like plane which featured a detachable base plate. The patent on the left (No. 3114/31) was entitled “Improvements in and connected with wood-working planes” and was applied for on the 18th July 1931. It was accepted on the 18th May 1932 and the invention statement, sourced from Trevor Semmens excellent book “Australian Planemakers”, tells us that:

“This invention has for its object to provide for the adjustment in wood-working planes of the cutting blade to work at varying angles in order to adapt the plane quickly and with a minimum of trouble to its duty. It will be possible by means of the invention to set the blade at high angles approximating to ninety degrees, and to use the blade reversed as a scraper. When used as a scraper the blade has its cutting edge burred.”

“The improvements are applied to the ordinary wood-working plane of commerce and especially relate to the provision of a slotted quadrant that can be and preferably is integrated with the back plate. The quadrant is adjustable over a frog adapted to adjustment longitudinally in the tool and is attached thereto and to the back plate by screws and bolts to alter and vary the angle of incidence of the cutter with the job at points within an arc of approximately forty-five degrees.”

The accompanying invention statement for patent No. 13879/33 on the left is titled “Improvements in and connected with the housing and feeding of the cutter blades in wood working planes.”. It was applied for on the 4th September 1933 and granted on the 6th August 1934, and informs us that:

The accompanying invention statement for patent No. 13879/33 on the left is titled “Improvements in and connected with the housing and feeding of the cutter blades in wood working planes.”. It was applied for on the 4th September 1933 and granted on the 6th August 1934, and informs us that:

“This invention relates to wood working planes and to the clamping and adjustment therein of the cutting blade.”

“In my Commonwealth Specification No. 3114 of 1931 the adjusting of the feed to the blade has been made from the back between the blade and the gripping handle of the plane, but in this instance the feed adjustment and also the clamping of the blade is provided through devices placed at the front of the tool.”

By all appearances it seems that the variable pitch frog is still in evidence on this plane, even though the emphasis of the patent relates to the movement of the blade forwards or backwards to regulate the depth of cut. With one of the controls present on the lever cap the design is reminiscent of a Stanley No. 164 low angle plane.

H. E. Watkinson’s third patent (which was actually the first one he lodged) was No. 3113/31 and was also applied for on the 18th July 1931 and accepted on 18th July 1932. This patent was for “An adjustable spokeshave plane” and states:

H. E. Watkinson’s third patent (which was actually the first one he lodged) was No. 3113/31 and was also applied for on the 18th July 1931 and accepted on 18th July 1932. This patent was for “An adjustable spokeshave plane” and states:

“This invention relates to a tool that can be described as a spokeshave plane for use in working wood and other like materials.”

“The ordinary plane as now used is grasped by the two hands of the operator, one in front and the other at the rear of the cutting blade.”

“In this invention a tool is provided wherein a grip by the operator is possible that will give him greater command over the tool. Means are also provided for adjusting the incidence of the cutting tool in the plane.”

“To this end, the improved tool is furnished with laterally extending handles, one being at each side of the cutter, as in a spokeshave, and elevated above the cutting tool edge to permit of the hands clearing the work when planing wide, flat surfaces. The body is further shaped to give a rest to each thumb at the back, and at the front are platforms, preferably curved, that act as rests for the index fingers. The remaining fingers and the hand grip the shaped lateral handles or horns.”

“The cutting member of the tool is mounted between the handles and is adapted to be moved over a quadrant to permit of the angle of incidence of the cutter to the work being altered and set as required.”

“The cutting member of the tool is mounted between the handles and is adapted to be moved over a quadrant to permit of the angle of incidence of the cutter to the work being altered and set as required.”

“The cutting member is mounted in a manner similar to that described in my Commonwealth Specification No. 3114 of the 18th day of July, 1931, that is to say in such a way as to permit of the cutter being adjusted in the plane to alter its angle of incidence to the work in hand.”

“It has been found preferable to make the face of the plane detachable from and adjustable upon the body, though it may be integral therewith, and there are stabilising bolts between the body and the backing plate.”

Wrap-Up

Whether or not the plane proved functional over time we cannot say as, with so few of them available, its difficult to determine if in fact they could go the distance and do the work as sufficiently as a “normal” bench plane would. It’s possible that the design on the Watkinson plane may not be sturdy enough and therefore cause the blade to chatter on the work, due primarily to the frog design. Not having access to a plane for testing purposes the claim of the plane’s usefulness will largely be untested. Having said that though, with so few of these planes around I’m not sure that I would want to test the practical uses, just in case the casting may indeed prove too fragile. Some things are best left untested.

One thing we can be thankful for, however, is the inventiveness and ingenuity that H.E. Watkinson, and others, have shown us over the past one or two centuries of metal plane making.

One thing we can be thankful for, however, is the inventiveness and ingenuity that H.E. Watkinson, and others, have shown us over the past one or two centuries of metal plane making.

Whether it be variable pitch, rotating frogs, dovetailed rosewood soles, self oilers, straight, squiggly or circular corrugations, names or grids cast into the sole – without creators such as these the world of the woodworking hand plane would be a whole lot less interesting.

NOTE: My thanks to Hans Brunner for descriptive details and pictures of the Watkinson plane, the Hand Tool Preservation Association of Australia (HTPAA) for additional pictures, and Trevor Semmens and his book “Australian Planemakers” for the illustrations and patent information.

It should also be mentioned that Mr. Watkinson’s sister stated, in October 1988, that the three inventions by Mr. Watkinson were never commercially manufactured.