Shodding Your Smoothing Plane With A Steel Sole

A disadvantage with wooden planes is that, when engaged in much repair work, the soles soon begin to show signs of wear. The smoothing plane seems to suffer the most, with the result that the sole has to be trued up frequently with an iron try-plane. Naturally, the plane becomes smaller and smaller. To prevent all this trouble, however, it is a good idea to face the sole of the plane with a thin plate of mild steel, the latter being prepared to shape and fixed with flat-head iron screws.

A smoothing plane reinforced in this manner is ideal for both fine and rough work, such as parquetry floors, table tops, and so on. Indeed, it would be worth while keeping such a plane for special jobs, especially those in which the going is tough.

A piece of 1/8 inch mild steel the exact size of the sole of the plane is required. Any sheet metal shop will be able to supply you. The sole of the plane is trued up in the usual way, i.e., it is clamped in the bench vice and planed with the iron and wedge in, the former drawn well back.

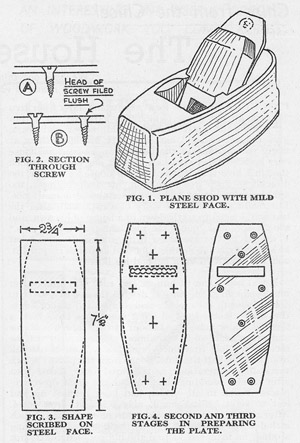

The shape of the plane and the mouth aperture is described on the plate as in Fig. 3. Much of the waste is cut away with a hacksaw and the mouth drilled as shown at Fig. 4. Screw positions are marked out, centre-punched, and drilled and countersunk to suit 1/2 inch by 6 flat-head iron screws.

Some woodworkers prefer to sink the screw heads fully into the plate so that the nicks remain as shown by the section (A), Fig. 2. Others prefer to countersink the holes so the screw heads project about halfway (B). When the heads are filed flush with the plate, no nicks show and thus give a better appearance to the plane. You could, nevertheless, always fill in the screw nicks with solder; they do look extremely ugly when filled with dust, glue and grease.

When fixed, clean out the mouth aperture with a file. The side edges should be filed at the same angle as the escarpment of the plane; the outside sides and ends of the plate are then roughed over and finished flush, using a coarse and a fine file. A pad or emery cloth is rubbed around ‘die edges to remove any sharpness; the nose end of the plate should be bevelled or rounded over.

Truing A Wooden Plane

After being in use for a considerable time the sole of a plane becomes worn and it is necessary to true it. A metal trying plane is the best tool to use, and it should be set fine so that the thinnest shavings are removed. The cutter and wedge should be in position because the wedge causes a slight distortion, and the sole is thus corrected whilst the plane is in working condition. The cutter should be drawn back about 1/8 inch so that it does not foul the plane used for trimming. It should be tested with the parallel strips as well as the straight edge.

NOTE: The above short articles have been reprinted from ‘The Woodworker’, Volume XLIV, Number 554, January 1940 and Number 555, February 1940. While much has changed with woodworking, the information contained here is as relevant today as it was over 70 years ago.

Last Updated: