Wooden Bench Plane Basics

The following passages have been transcribed from the book “Bench Work In Wood: A Course Of Study And Practice Designed For The Use Of Schools And Colleges” by the writer W.F.M. Goss. which was first printed by Ginn & Co, Boston in 1888. W.F.M. Goss was a professor of practical mechanics at Purdue University in Lafayette, Indiana. Many of the illustrations in the book were produced by Mr. M. Golden, of the School of Mechanics and Engineering at Purdue University.

The following passages have been transcribed from the book “Bench Work In Wood: A Course Of Study And Practice Designed For The Use Of Schools And Colleges” by the writer W.F.M. Goss. which was first printed by Ginn & Co, Boston in 1888. W.F.M. Goss was a professor of practical mechanics at Purdue University in Lafayette, Indiana. Many of the illustrations in the book were produced by Mr. M. Golden, of the School of Mechanics and Engineering at Purdue University.

Although the book is well over a hundred years old, much of the information contained within it is still quite relevant and valid today. Certainly when it comes to hand planes not much has actually changed within that period – apart from the advances in tool steel technology. Back then it was still a matter, largely, of welding the more expensive steel cutting edge to a softer iron blade. This was mainly because the new steels of the day were quite expensive to buy on a tradesman’s wages, and woodworkers were still used to having the thicker wooden type plane blades in their hand planes.

Times were changing, however, and one of the things that makes this book interesting is that around about this time there were great changes and innovations happening within the woodworking and cabinetmaking industries. Wooden planes were on the way out and, for the past decade or so, “brand new” metal planes of the Bailey design were becoming increasingly more popular and being sold in great quantities by many different makers, large and small. While W.F.M. Goss mainly writes about the use and care of traditional wooden planes in this book, he also mentions these new-fangled Bailey hand planes.

I’ve decided to break up the text and have it as several different articles for the site, however, as its a bit long to have it as one piece on a web site. Also, the fact that each “section” is essentially self-contained and concentrates on specific areas it just makes more sense to do it this way. This first section deals with wooden bench planes and how to use them. It identifies the main types – smooth planes, jack planes, fore planes and jointers – and in what situations they’re best suited to. It also includes some information on plane blades and how they work.

Planes and Plane-like Tools

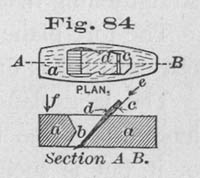

The plan and the section, Fig. 84, show a smooth plane. The stock a, when of wood, is usually beech. In it is an opening, or “throat”, b, which receives the iron c>; this is held in place by the wedge d. The lower part of the opening is called the mouth; and, as shown by the figure, the shaving passes into the mouth, and out through the throat. The bottom of the plane, which rests upon the work, is called it’s “face”. The iron usually stands at an angle of 45 degrees with the face.

The plan and the section, Fig. 84, show a smooth plane. The stock a, when of wood, is usually beech. In it is an opening, or “throat”, b, which receives the iron c>; this is held in place by the wedge d. The lower part of the opening is called the mouth; and, as shown by the figure, the shaving passes into the mouth, and out through the throat. The bottom of the plane, which rests upon the work, is called it’s “face”. The iron usually stands at an angle of 45 degrees with the face.

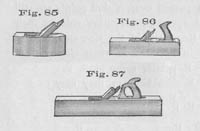

The bench-workers set of planes comprises a smooth-plane, Fig. 85, which is about 8″ in length; a jack-plane, Fig. 86, which is from 12″ to 14″ in length; a fore-plane, Fig 87, from 22″ to 26″ in length; and a jointer, from 28″ to 30″ in length. Similar purposes are served by the jointer and the fore-plane, the former being unnecessary except for large surfaces that are to be planed with accuracy.

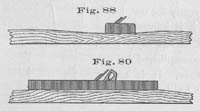

The length of the Plane-Stock determines, in a measure, the straightness of the work. Thus, a smooth-plane, if used on an uneven surface, will, as shown by Fig. 88, rise over elevated portions and settle in hollows, taking its shaving without interruption, and producing no great change in the outline of the surface, while a fore-plane or jointer similarly applied will, as shown by Fig. 89, cut only on the higher parts, and by so doing, produce an even surface.

The length of the Plane-Stock determines, in a measure, the straightness of the work. Thus, a smooth-plane, if used on an uneven surface, will, as shown by Fig. 88, rise over elevated portions and settle in hollows, taking its shaving without interruption, and producing no great change in the outline of the surface, while a fore-plane or jointer similarly applied will, as shown by Fig. 89, cut only on the higher parts, and by so doing, produce an even surface.

The stock of a smooth-plane is made short so that, by its use, a surface may be smoothed without incurring the necessity of straightening it.

The fore-plane will smooth as well as the smooth-plane, but not until it has first straightened the surface.

The fore-plane will smooth as well as the smooth-plane, but not until it has first straightened the surface.

The jack-plane is used for cutting heavy shavings, and its length bears no relation to the character of the work expected of it, but is such as it will enable the workman to grasp it easily and firmly.

A “Plane-Iron”, known also as a “plane-bit”, for a wooden plane is of iron overlaid in part with steel. It’s cutting edge is maintained in precisely the same way as that of a chisel. The angle of the cutting wedge, however, for all except the jack-pane may be more acute.

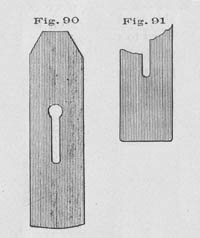

The outline of the cutting edge, unlike that of a chisel, is never straight, being for the jack-plane slightly curved, as shown by Fig. 90, and for the smooth-plane and fore-plane (also for the jointer) of the form shown by Fig. 91. Being used for heavy work and frequently removing shavings as thick as one-sixteenth of an inch, the jack-plane, if its cutting edge were straight, would produce in the work at each stroke a rectangular channel from which the shaving must be torn as well as cut. Such a shaving would be likely to stick fast in the throat of the plane, or, under most favorable conditions, would require a large amount of force for its removal. A shaving removed by the iron represented in Fig. 90, however, is not rectangular in section, but thick in the middle, tapering gradually to nothing at the edges. This form of iron is best adapted to the removal of a large amount of material at a stroke, but it leaves a succession of grooves upon the work which must be smoothed off by another plane.

The outline of the cutting edge, unlike that of a chisel, is never straight, being for the jack-plane slightly curved, as shown by Fig. 90, and for the smooth-plane and fore-plane (also for the jointer) of the form shown by Fig. 91. Being used for heavy work and frequently removing shavings as thick as one-sixteenth of an inch, the jack-plane, if its cutting edge were straight, would produce in the work at each stroke a rectangular channel from which the shaving must be torn as well as cut. Such a shaving would be likely to stick fast in the throat of the plane, or, under most favorable conditions, would require a large amount of force for its removal. A shaving removed by the iron represented in Fig. 90, however, is not rectangular in section, but thick in the middle, tapering gradually to nothing at the edges. This form of iron is best adapted to the removal of a large amount of material at a stroke, but it leaves a succession of grooves upon the work which must be smoothed off by another plane.

The form of the cutting iron in the smooth-plane and the fore-plane, as shown by Fig. 91, is straight throughout the greater portion of its width, and slightly rounded at the corners. The objections urged against the use of such an iron as this in the jack-plane, do not apply to its use in the smooth-plane or the fore-plane, because the jack-plane, to fulfill its office, must remove a heavy shaving; the smooth-plane or the fore-plane, unless the surface upon which it acts is very much narrower than the width of the plane, is required to remove a shaving whose thickness rarely exceeds that of a sheet of paper. The groove caused by the removal of so delicate a shaving, is sufficiently blended with the general surface of the work, by the rounded corners of the iron.

If a rough board is to be made smooth, or if a considerable amount of material is to be removed to bring a piece of wood to size, most of the surplus stock should be taken off by the jack-plane, after which the smooth-plane should be used to give the surface desired. If the finished surface is to be straight as well as smooth, the fore-plane should follow the jack-plane. It is never necessary to follow the jack-plane with both the smooth-plane and the fore-plane.

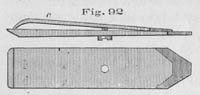

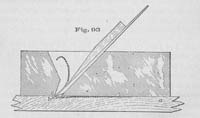

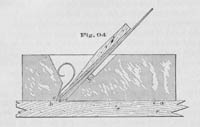

The Cap. — A supplementary iron, or “cap”, shown by c, Fig. 92, is fastened to most plane-irons. Its use is well illustrated by the two sections, Fig. 93 and 94. The single iron will do smooth work as long as the grain of the wood is favorable, as shown at a. When the grain becomes obstinate, as in b, which causes it to split in advance of the cutting edge, below the reach of which it breaks, leaving a surface extremely rough. The office of the cap is to break the shaving as soon as possible after it is cut, Fig. 94, and thus prevent a gain of leverage on its part.

The Cap. — A supplementary iron, or “cap”, shown by c, Fig. 92, is fastened to most plane-irons. Its use is well illustrated by the two sections, Fig. 93 and 94. The single iron will do smooth work as long as the grain of the wood is favorable, as shown at a. When the grain becomes obstinate, as in b, which causes it to split in advance of the cutting edge, below the reach of which it breaks, leaving a surface extremely rough. The office of the cap is to break the shaving as soon as possible after it is cut, Fig. 94, and thus prevent a gain of leverage on its part.

The distance at which the cap is set from the edge of the iron, must vary with the thickness of the shaving taken. For a smooth-plane or a fore-plane, a thirty-second of an inch is frequently not too close, while for a jack-plane an eighth of an inch may not be too great a distance.

The distance at which the cap is set from the edge of the iron, must vary with the thickness of the shaving taken. For a smooth-plane or a fore-plane, a thirty-second of an inch is frequently not too close, while for a jack-plane an eighth of an inch may not be too great a distance.

A cutting iron and cap together are frequently spoken of as a “double iron.”

Narrowness of Mouth in a plane is the chief element in the production of smooth surfaces. If, in Fig. 94, that portion of a stock in advance of the iron, marked c, were wanting, the shaving, having nothing to hold it down, would rarely be broken, notwithstanding the presence of the cap. A wide mouth would produce a similar effect. This being true, whatever other conditions there may be, the wider the mouth is, the less frequently the shaving will be broken and, in obstinate grain, the rougher will be the work.

To Adjust the Iron. — To set the iron deeper, so that a heavier cut may be taken, strike it a light blow, as indicated by the arrow e, Fig. 84. If a lighter cut is required, strike the stock as indicated by the arrow f. When the iron is in the right position, a light blow will tighten the wedge. To remove the iron and wedge, turn the plane over so that the face is uppermost, grasp the iron and wedge with the right hand, hold the back end of the plane between the thumb and finger of the left, and strike the stock at f upon the surface of the bench. A single blow is usually sufficient.

To Adjust the Iron. — To set the iron deeper, so that a heavier cut may be taken, strike it a light blow, as indicated by the arrow e, Fig. 84. If a lighter cut is required, strike the stock as indicated by the arrow f. When the iron is in the right position, a light blow will tighten the wedge. To remove the iron and wedge, turn the plane over so that the face is uppermost, grasp the iron and wedge with the right hand, hold the back end of the plane between the thumb and finger of the left, and strike the stock at f upon the surface of the bench. A single blow is usually sufficient.

Never strike the plane while it is resting on the bench or any support that is firm. It should be held in the hand clear of everything; but, if this is not convenient, one end may rest on the knee.

To set the iron in a wooden plane, hold the stock in such a way that, while the face rests on the hand, the end of the forefinger may extend across the mouth. Put the iron in place, allowing its cutting edge to rest on the forefinger, which should keep it from projecting. Insert the wedge, push it down with the thumb, and by a light blow with the hammer drive the iron down until its projection beyond the level of the face is equal to the thickness of the shaving that the plane is to take; a single tap on the wedge will then tighten the iron in place. The distance that the iron projects, can easily be determined by sighting along the face of the plane.

The wedge must not be driven too hard, for a plane may be so distorted by a hard-driven wedge as to make it incapable of doing good work. The iron will be held in place even when the wedge is so loose that it may be drawn out with the fingers.

Notwithstanding the fact that wooden plane-stocks are made from material little affected by atmospheric influences, they will warp enough, especially when nearly new, to bring the face considerably out of a true plane. When, from this cause, the plane fails to do good work, it must be jointed.